Dakota Gasification Company

Headquarters:

1717 East Interstate Avenue | Bismarck, ND 58503-0564 USA

701.223.0441 | 1.800.242.2372

Great Plains Synfuels Plant

420 County Road 26

Beulah, ND 58523-9400 USA

701-873-2100

A subsidiary of:

What feels effortless now—a simple flip of a switch—was once a struggle for entire communities. Not

so long ago, electricity in rural America was scarce and uncertain.

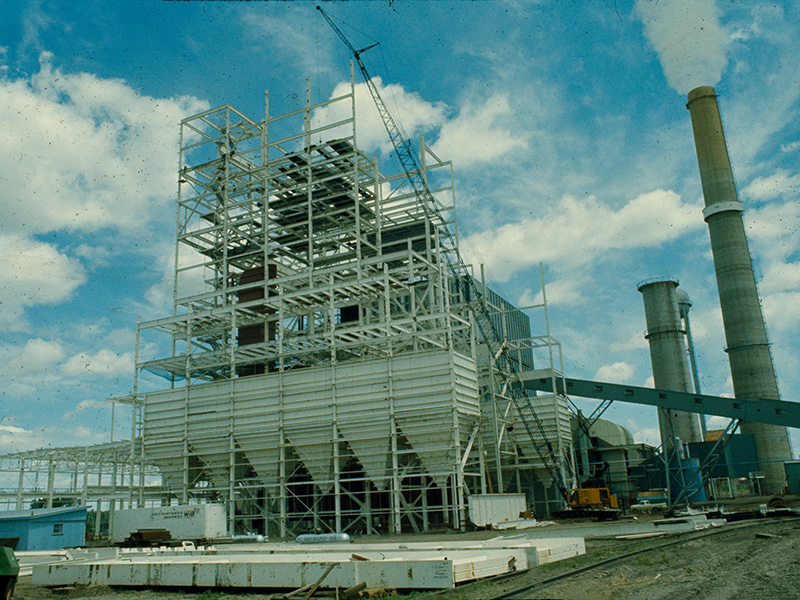

That started to shift in the late 1960s when Basin Electric built its first power plant, the Leland Olds Station, which would become a landmark piece of the power grid. Today, that pioneering achievement is celebrating 60 years of keeping the lights on for Basin Electric’s members and rural America.

Named for Leland Olds, a leader in the effort to develop a regional approach to electric power supply, Leland Olds Station’s first generating unit began producing 220 megawatts (MWs) of power in 1966. With 2,785 tons of steel framework rising 163 feet above the prairie, the plant was built four miles southeast of Stanton, North Dakota. At the time, it was the largest lignite-fired power plant in the Western Hemisphere, costing the cooperative $36 million to build.

Lignite coal was chosen as the fuel source because of its abundance and local availability. At the time, Assistant Secretary for Water and Power Development in the U.S. Department of the Interior Ken Holum said, “Lignite coal is going to work to generate cheap power for farmers, to provide a new major source of energy for the country, to provide jobs now and more jobs in the future for Dakota citizens.”

When Unit 1 went online, it began sending power to a growing Basin Electric membership—105 members in eight states. As demand grew, the need for additional generation became clear. In 1975, commercial operation started for Leland Olds Station Unit 2, a 440 MW unit located adjacent to Unit 1. Construction of the second unit cost $109 million.

A plant can generate electricity, but it’s the people running it who truly keep power flowing. Their dedication and skill turn a facility into a community and a job into a shared mission.

When Tim Forsch, electrical supervisor, began working at Leland Olds Station in 1978, the shiny new facility made a big impression.

“Right away I noticed that the people were friendly and welcoming. Everyone took a lot of pride in their work and what the plant looked like,” Forsch reflects. “I remember being impressed by how environmental excellence and compliance were very high on the priority list—and it’s still that way today.”

Forsch has held a handful of positions since he began working at Leland Olds Station, and he says many have been challenging but enjoyable. Still, his favorite role might surprise you.

“One of the jobs we used to rotate into was giving tours around the plant,” Forsch shared. “They often consisted of local co-ops and members, sometimes high schoolers and job fair kids who were interested in how electricity was generated. It was fun to walk them through the process and share what we’re proud of.”

Tony Michlitsch, plant superintendent, has been with Leland Olds Station nearly 22 years and says the many roles he’s held at the plant have shaped his perspective.

“Every position I’ve had holds an important part in the operation of the plant, and I’ve really enjoyed them all. Each operates a different portion of the plant that ties in together with the other positions, so they’ve helped me understand how and why each position does what they do,” he says.

As one might expect, a lot has changed at Leland Olds Station since it began operations 60 years ago. From an overhaul of the control system to scrubber installations, the plant is safer, more efficient, and environmentally compliant because of improvements and modernizations that have been made.

“It’s amazing how technology has changed,” Forsch says. “We started with large mechanical benchboards which formed and housed the boiler control panels, and our controls were largely pneumatic. Everything was very manual, where now we have most all of the processes controlled by computers.”

“In this industry, we have to continue to grow and change to keep people safe and make things run

more efficiently,” Michlitsch added. “We are continuously planning for the next outage, looking for better parts or equipment, and developing new ways to make things better.”

The reasons Leland Olds Station was originally constructed—meeting growing energy demand, modernizing agriculture, economic development, and energy reliability and independence—are still as relevant today as they were when the plant was first built. Leland Olds Station continues to stand as a vital resource for communities across the region, delivering reliable power to 139 member cooperatives in nine states and supporting the farms, businesses, and families who depend on it every day.

“Basin Electric stands as a symbol; it is more than just a power supplier,” according to a Basin Electric publication from February 1966. “The rural residents of the Missouri Basin … have created one of the largest homegrown ventures in the region. They have done it in a way that (is) incontrovertibly sound according to business principles. They have done it by themselves and for themselves. The benefits will flow to the entire region.

Dakota Gasification Company

Headquarters:

1717 East Interstate Avenue | Bismarck, ND 58503-0564 USA

701.223.0441 | 1.800.242.2372

Great Plains Synfuels Plant

420 County Road 26

Beulah, ND 58523-9400 USA

701-873-2100

A subsidiary of:

Basin Electric wants all interested and qualified candidates to apply for employment opportunities. If you are an applicant with a disability who is unable to use our online tools to search and apply for jobs, or who needs other assistance or accommodations, please contact us at 701-223-0441. Please indicate the specifics of the assistance needed or provide your contact information, and a Basin Electric Human Resources representative will contact you. Basin Electric is an Equal Employment Opportunity Employer regarding race, color, religion, sex, sexual orientation, gender identity, national origin, disability, and veterans status.