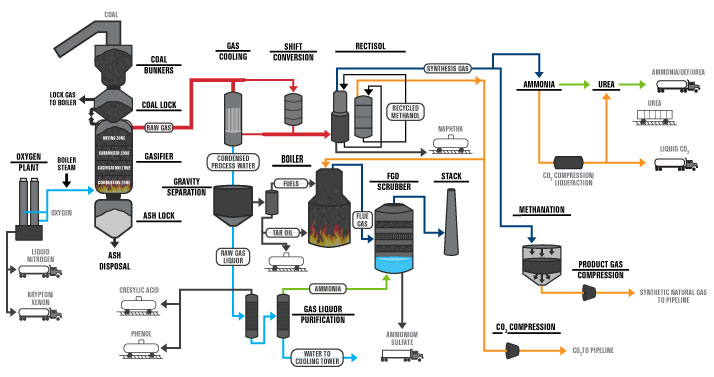

Step by step

Gasifying coal involves dismantling its molecular structure in the gasification reactors and reassembling the resulting hydrogen and carbon as methane gas (methanation), which is then sent to a pipeline. The heart of the Synfuels Plant is its 14 gasifiers. These gasifiers are cylindrical pressure vessels, 40 feet high with an inside diameter of 13 feet.

- Each day 18,000 tons of lignite are fed into the top of the gasifiers.

- Steam and oxygen are injected into the bottom of the coal beds causing intense heat: 2,200 degrees Fahrenheit.

- The hot gases break down the molecular bonds of coal and steam, releasing compounds of carbon, hydrogen, sulfur, nitrogen and other substances to form a raw gas that exits the gasifiers.

- The raw gas is cooled.

- Tar oils, phenols, ammonia and water products are condensed from the gas stream and purified and sent on.

- The gas moves to a cleaning area where further impurities are removed.

- Methanation occurs when the cleaned gas passes over a nickel catalyst causing carbon monoxide and the remaining carbon dioxide to react with free hydrogen to form methane.

- Carbon dioxide is removed.

- The gas is then cooled, dried, and compressed, and enters the pipeline with a heating value of 975 Btu per cubic foot.